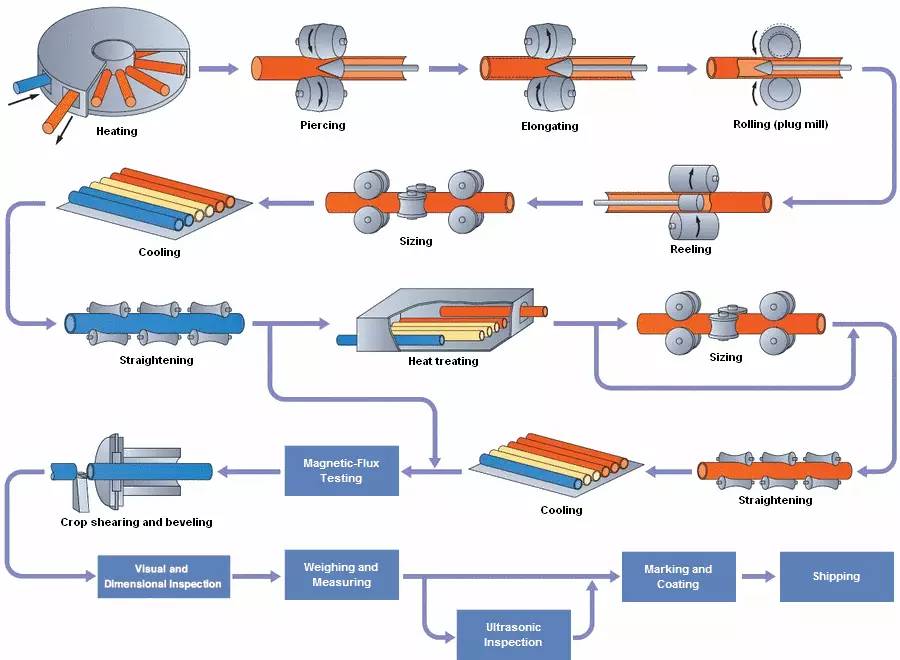

1 Main production process of hot-rolled seamless steel pipe (main inspection process):

Preparing and Inspection of Tube Billet Heating of Tube Billet Piercing Rolling Reheating of Waste Liquid Tube Fixing (Reducing) Diameter Heat Treatment Straightening of Finished Tube Finishing Inspection (Nondestructive, Physicochemical, Taiwan Inspection) Storage

2 cold rolling (drawing) seamless steel pipe main production process

Blank preparation → pickling lubrication → cold rolling (pull) → heat treatment → straightening → finishing → inspection

Hot rolling seamless steel pipe production process flow chart:

Source: China Metallurgical News Agency

Tips

statement:

1. If you reprint the contents of this platform, you must indicate the source. The works of non-Bengang News are reproduced from other media. The purpose of the reprint is to transmit more information. It does not represent the platform. If you try to check the source, you will not be able to find the source. If you have any omissions, please contact the original or contact or delete it in time.

2. If any work is marked as "rejected," we will not reprint it.

3. For malicious and false reports, we reserve legal rights